You are no doubt doing your best to keep abreast of technological changes in process scale-up for the refining and petrochemical industries. Traditionally, there has been a scale-up step from the laboratory to a pilot stage followed by scale-up to a commercial “demonstration” plant, prior to committing to commercial production due to the: a) complexity of the processes; b) requirement to understand key parameters such as recycle and impurities; c) catalyst deactivation and byproduct threats; d) need for sufficient product for application evaluations; and e) significant risk and expense involved in a full production scale-up. TCGR’s The Catalytic Advances Program (CAP) is playing an important role in keeping industry decision-makers and R&D scientists up to date.

You are no doubt doing your best to keep abreast of technological changes in process scale-up for the refining and petrochemical industries. Traditionally, there has been a scale-up step from the laboratory to a pilot stage followed by scale-up to a commercial “demonstration” plant, prior to committing to commercial production due to the: a) complexity of the processes; b) requirement to understand key parameters such as recycle and impurities; c) catalyst deactivation and byproduct threats; d) need for sufficient product for application evaluations; and e) significant risk and expense involved in a full production scale-up. TCGR’s The Catalytic Advances Program (CAP) is playing an important role in keeping industry decision-makers and R&D scientists up to date.

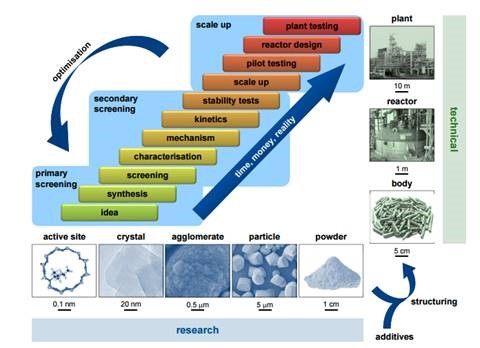

Scaling-up the catalyst preparation procedure is also not a straightforward task. The catalytic activity during pilot testing will not necessarily be the same as in laboratory experiments. In 2009 TCGR’s Catalytic Advances Program (CAP) produced an in-depth report for its members, entitled “Catalytic Process R&D Scale-Up: Challenges and Issues.” In the past 7-8 years, however, computer modelling and other techniques have improved to a point where accurate prediction can be made regarding scale-up. Thus, the new report, “Catalytic Process R&D Scale-Up II” is in development. Why is this report essential?

Catalytic process R&D scale-up is a timeless subject that needs to be studied and understood “in time” with advances on many technological fronts. This CAP report documents the complex and varied technical challenges that are components of scaling-up catalytic processes from the laboratory to a pilot stage and then on to commercial reactors. Specifically, it brings to the foreground new techniques used to scale-up catalytic reactions.

Source: “From powder to technical body: the undervalued science of catalyst scale up”.

Source: “From powder to technical body: the undervalued science of catalyst scale up”.

http://pubs.rsc.org/en/content/articlelanding/2013/cs/c3cs60076a#!divAbstract

New computer simulation technology and other improved modelling techniques make it possible to begin the scale-up simulation in a smaller pilot plant to predict what the effects of scale-up might be, thus saving time and money by jumping or combining steps to reduce scale up resources. Additionally, and unlike current articles or reports on this topic, this CAP report not only provides case studies demonstrating how current processes have been scaled-up, it also documents the critical steps required and mistakes to avoid when scaling-up processes which provides, in effect, a tutorial, offering a “how to” component to its scope.

In determining the subject of its exclusive report, TGCR’s CAP members reviewed 6 potential report topics for 2017 and hand-selected three (3), one of which is entitled, “Catalytic Process R&D Scale-Up II” to lead the way. This indicates that where, how, and from whom scale-up techniques are being derived and implemented is of utmost importance.

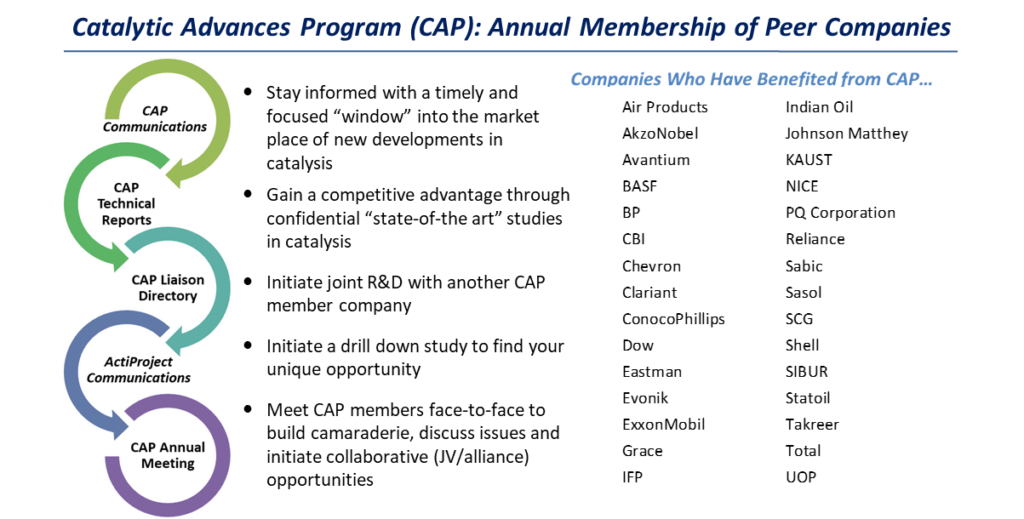

Don’t be left behind! Align with leading industrial member-companies like those found in the graphic below. This is the only way to get TCGR’s in-depth and unparalleled report, “Catalytic Process R&D Scale-Up II.”

TCGR’s Catalytic Advances Program (CAP) is an information resource for research and development organizations in the chemical, polymer, and petroleum industries. Depending on their membership choice, CAP members may receive all three or just two annual technical reports as well as the weekly newsletter known as CAP Communications. This newsletter provides the latest updates on technical breakthroughs, commercial advancements, noteworthy conference proceedings, and exclusive development opportunities. Membership also includes attendance at a CAP Annual Meeting, with dates, location, and topics selected by the membership.

More information about this and other services of TCGR’s Catalytic Advances Program (CAP) can be seen at:

https://www.catalystgrp.com/php/tcgr_catalyticadvancesprogram.php.

You can also call +1-215-628-4447 or e-mail Matthew A. Colquitt at mcolquitt@catalystgrp.com, and we’ll be happy to discuss these and other interesting membership benefits.

* * * * *

The Catalyst Group Resources (TCGR), a member of The Catalyst Group, is dedicated to monitoring and analyzing technical and commercial developments in catalysis as they apply to the global refining, petrochemical, fine/specialty chemical, pharmaceutical, polymer/elastomer and environmental industries.